Lip Seal Design In Ball Valve

Lip seal is a type of spring-energized ring that is widely used in ball valves serving various oil and gas fields because of its excellent sealing performance.

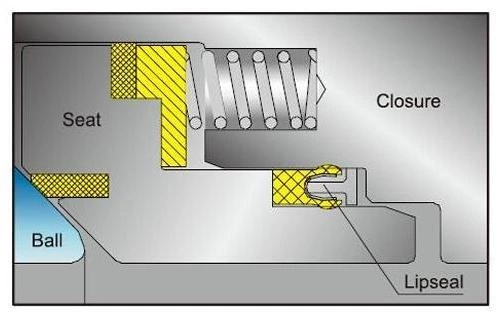

Lip-seals were introduced to the oil and gas sector primarily to solve reliability and durability problems caused by the performance limitations of elastomeric seals (e.g. O-Ring). Lip seals are pressure-assisted sealing devices, consisting of a PTFE jacket or other polymer, partially encapsulating a corrosion-resistant metal spring energizer.

The advantage of lip seals is that they can "self-seal"; that is, their sealing performance increases with the increase in pressure. In addition, it can reduce friction, have a long service life, and be applied to more harsh environments and extreme temperatures and pressures.

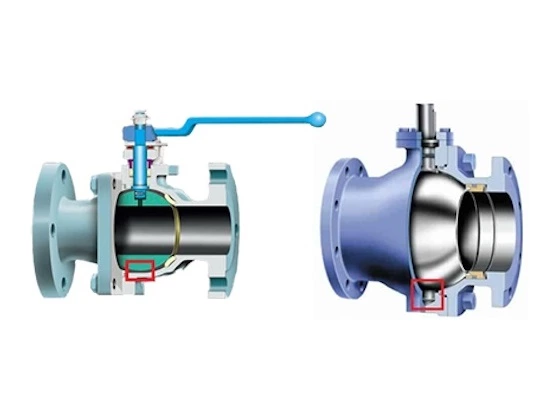

Ball valve lip seal design

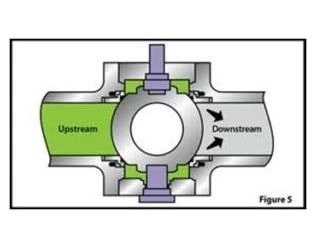

Sealing Principle of Lip Seal

The high-pressure medium escapes under the action of pressure, and the escaping gas or liquid spreads along the gap between the parts. After reaching the lip seal position, due to the preload of the lip seal energy storage spring, the sealing lip is pressed against the outer wall of the part so that the medium with slightly lower pressure cannot pass through the barrier. With the gradual increase of the escaping medium, the pressure in the lip seal ring groove gradually rises. At this time, under the pressure of the lip seal, the sealing lip will better fit on the inner and outer walls of the parts. Finally, the pressure in the container cavity will reach a balance, and the lip seal will realize the sealing.

Lip seal is a pressure auxiliary sealing device with polytetrafluoroethylene (or other polymeric materials) jacket that is specially equipped with a corrosion-resistant metal energy storage spring.

Optional Materials

1. Common materials for sealing jackets:

Pure PTFE, modified PTFE, polymer-filled PTFE, HDPE, ETPE, PEEK, etc.

2. Common materials for energy storage springs:

304 SS, 316 SS, Inconel, Elgiloy, 17-7ph, and 301 SS/302 SS/Hestelloy nickel base alloy, etc.

Application

- Low-temperature or high-temperature top-entry ball valve

- Three-piece trunnion mounted ball valve at -100 °C

- Low-temperature butterfly valve at -196 °C