Floating Ball Valve Vs Trunnion Ball Valve

Floating and trunnion ball valves are both quarter-turn shut-off valves. They have a tight sealing mechanism that prevents leaks. This makes them suitable for applications where high-pressure and high-temperature fluids are present. Floating and trunnion ball valves open and close quickly. They have low torque, which makes them easier to handle.

How Does A Trunnion Ball Valve Work?

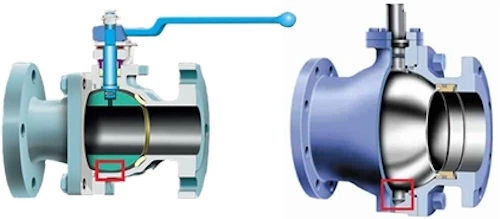

In a trunnion ball valve, the ball is inserted in a central bottom shaft, which is called the trunnion. The ball is fixed between the stem and the trunnion, which indicates that the ball is not floating but fixed and centered.

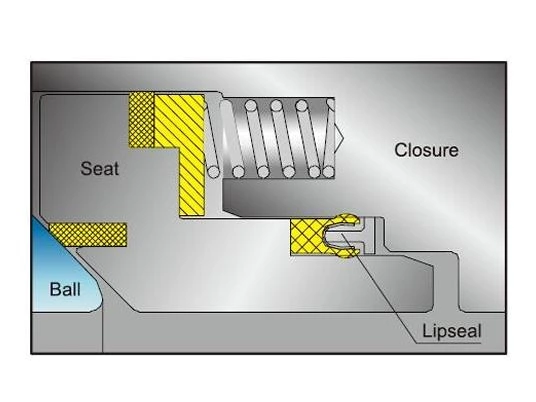

Trunnion-mounted ball valves are effective in both low and high pressure situations. In low or no-pressure situations, the spring-loaded seats will create a seal. In high pressure, the inline pressure presses the seats against the ball, causing the tightness.

Advantages:

Trunnion-mounted ball valves are designed for heavy-duty applications, ensuring exceptional reliability and efficiency. The innovative trunnion design provides support for the ball at both ends, enabling it to withstand the forces generated by high fluid pressure and flow rates.

Floating Ball Valve Vs Trunnion Ball Valve

How Does A Floating Ball Valve Work?

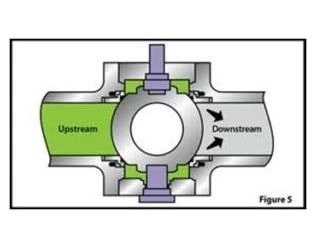

In a floating ball valve, the ball floats in the valve body and moves in response to the pressure difference between the upstream and downstream. The ball is pushed against the downstream seat by the in-line pressure, resulting in tightness.

Advantages:

Floating ball valves have small flow resistance, a simple structure, good sealing performance, and are cost-effective.

Floating Ball Valve Vs Trunnion Ball Valve

| Content | Floating ball valve | Trunnion ball valve |

| Function | On-off | On-off |

| Shut-off time | Quick (quarter turn valve) | Quick (quarter turn valve) |

| Size range | 1/2”-8” Class 150 & 300 1/2”-4” Class 600 1/2”-2” Class 900 1/2”-1-1/2” Class 1500 & 2500 |

2” and bigger Class 150- 2500 |

| Sealing seat | Upstream & downstream seat seal at the same time |

Downstream seat |

| Torque | Higher | Lower |

| Seat structure | Seat support | Spring loaded seat |

| Self-relieving seat | Yes | Yes |

| Drain valve | Yes | Not needed |

| Maintenance | Less | More |

| Valve part | Less | More |

| Price | Lower | Higher |

Why Floating Ball Valves Are Not Suitable For Big Sizes

Since the ball covers the entire flow bore, all the force in the stream is pushing against the ball to force it into the seat. If the ball gets too large and the pressure is too high, the force will be so great on the seat that the valve cannot be operated because the operating torque would be too high.